September 29 2004

Continuous heating of {111} rod

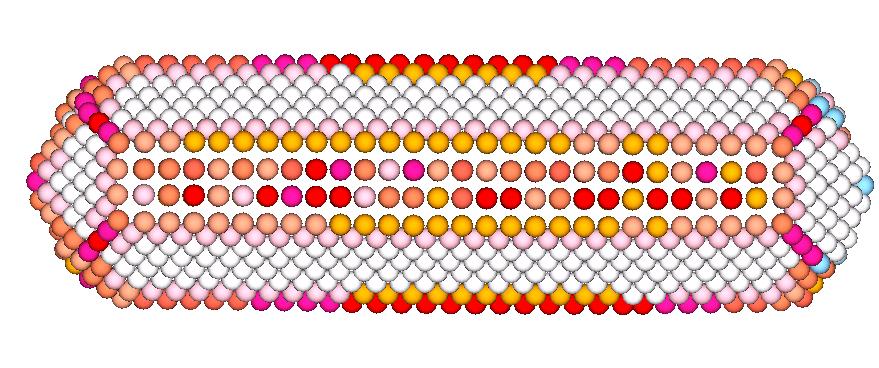

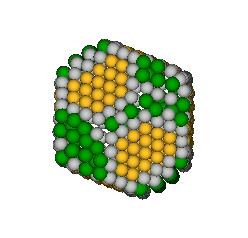

Gold {111} planes were built up layer by layer to form an fcc body, and carved

out to form the rod mostly covered by {111} facets. The rod has an aspect ratio

of 3 and a width of about 2.8 nm, with 3411 atoms. The sharp edges where two

side {111} facets met were truncated to be {100} facets, so that the cross

section of the rod is near spherical. The end caps are also truncated to have

two {111} and two {100} facets at each end, so that the ends got rounder.

The constructed rod went through a constant temperature MD at 5K for 10^5 steps

(430 ps) to relax the surface.

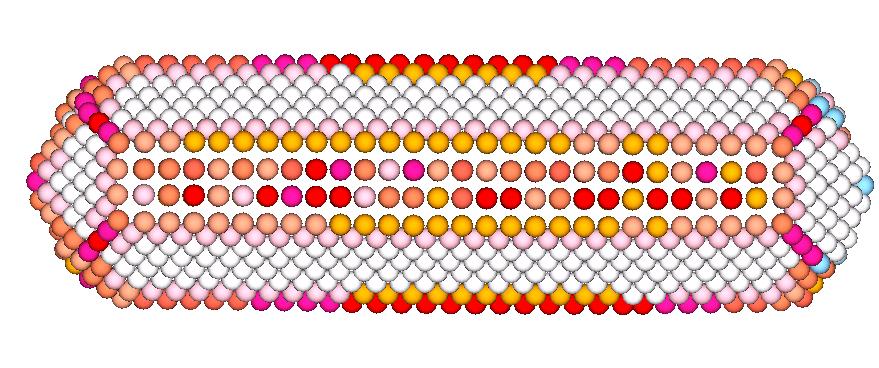

Colored by local curvature

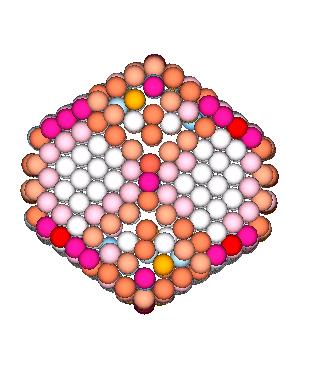

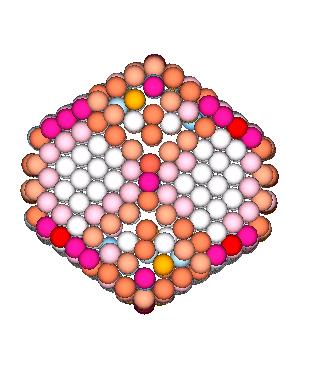

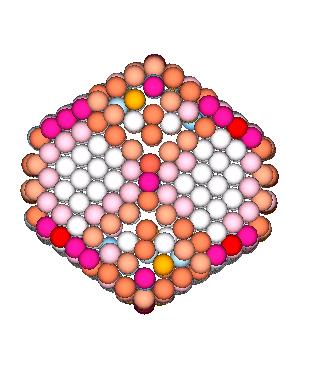

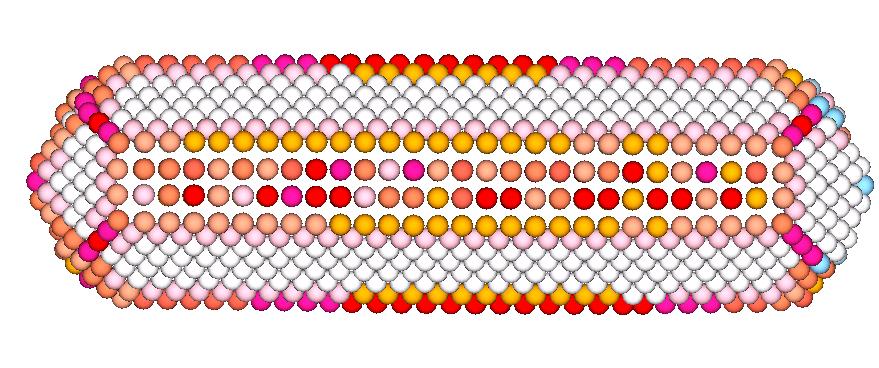

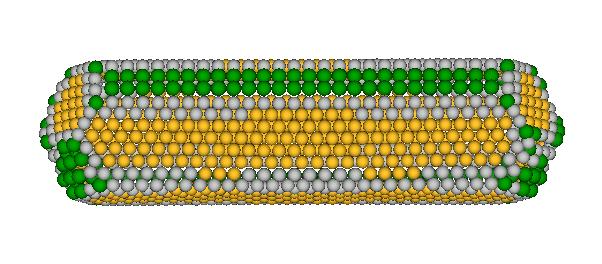

The following two pictures are the views of the last configuration at 5K

colored by local maximal curvature.

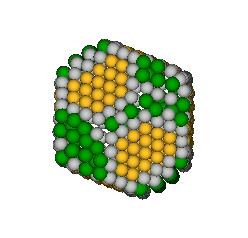

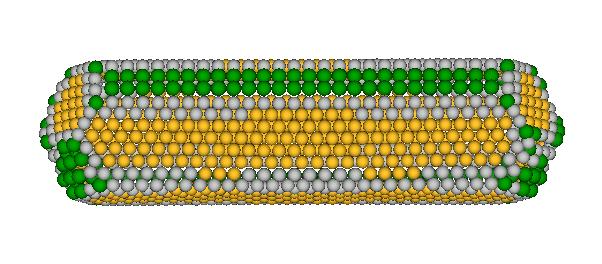

Colored by facets

The same configuration has also been colored by type of facets. Yellow atoms

are {111} facets, green atoms are {100} facets, and gray are others.

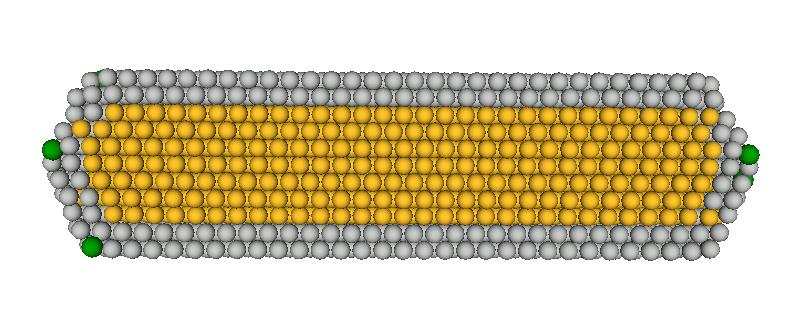

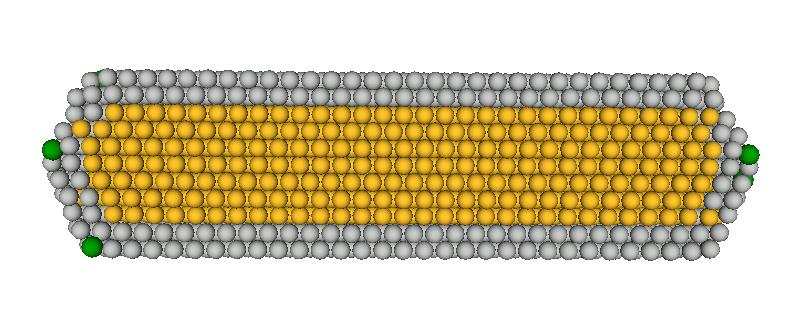

Colored by local structure

The above configuration has been cut in half and colored with the local 3D

structure to show the pure fcc interior. Yellow atoms are fcc,

green atoms are hcp, and gray are others.

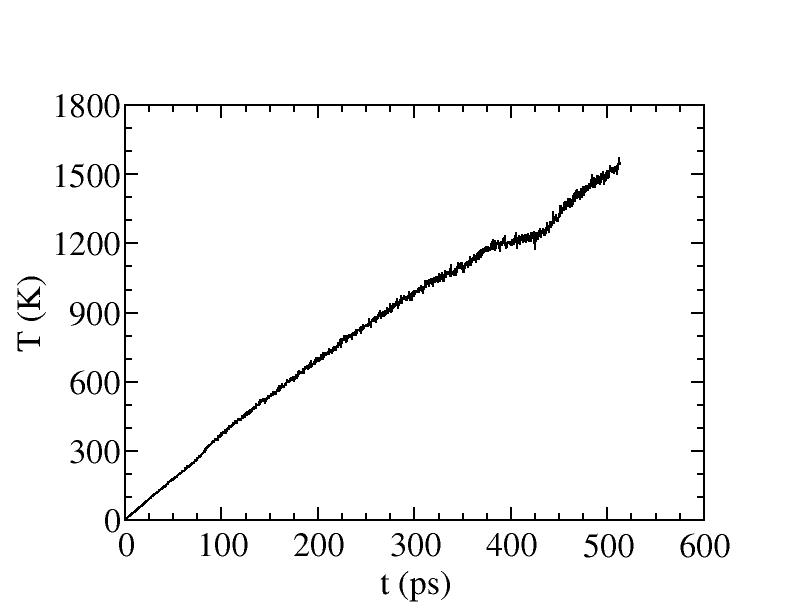

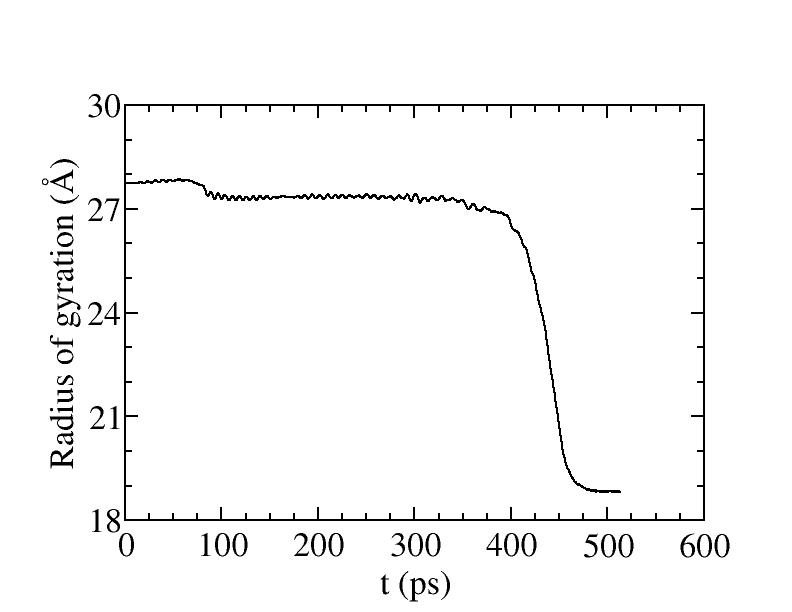

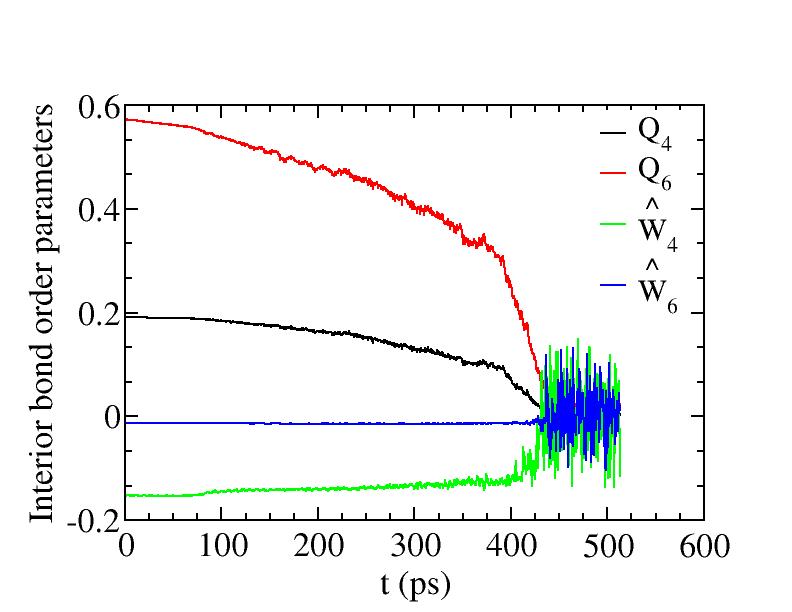

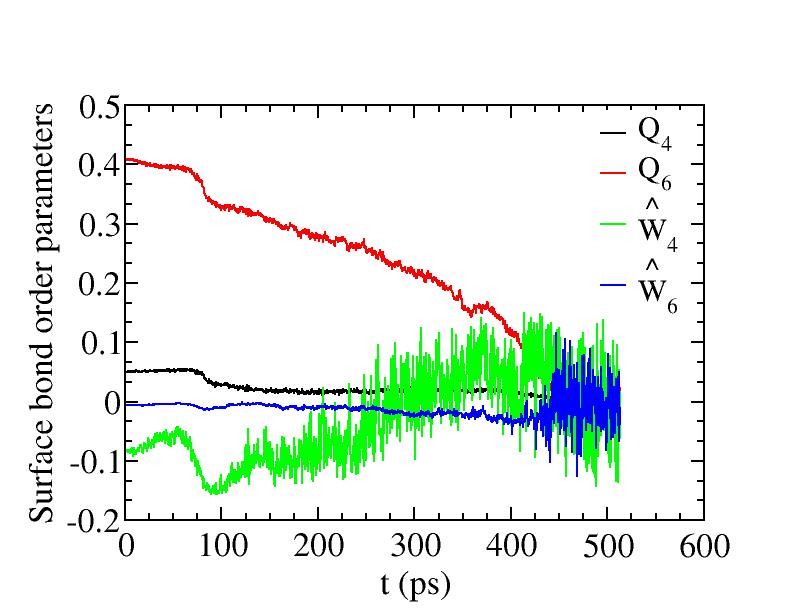

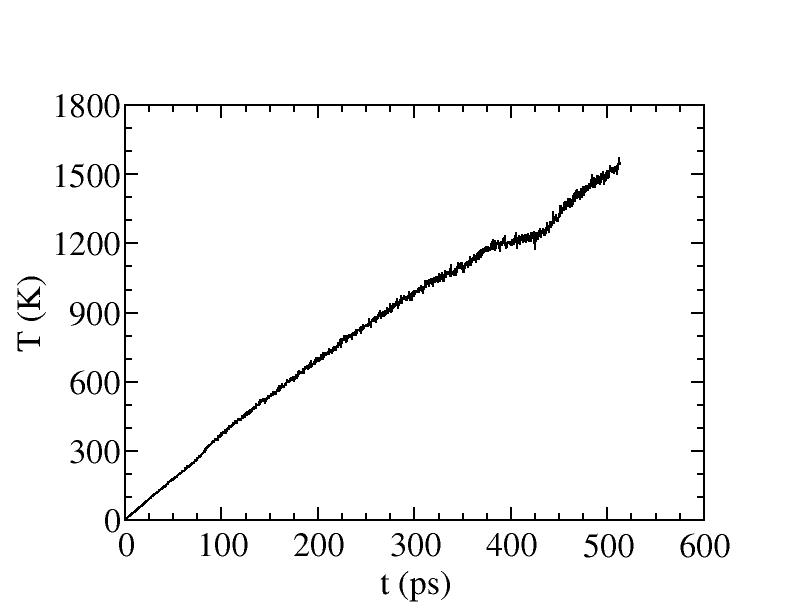

Continuous heating

The above configuration then went through a continuous heating MD procedure

with a heating rate of 7*1012K/s. Note that the surface atoms were

distinguished by number of neighboring atoms, not the cone algorithm.

The sampled configurations in .xyz file format can be downloaded

here.

Temperature vs. time

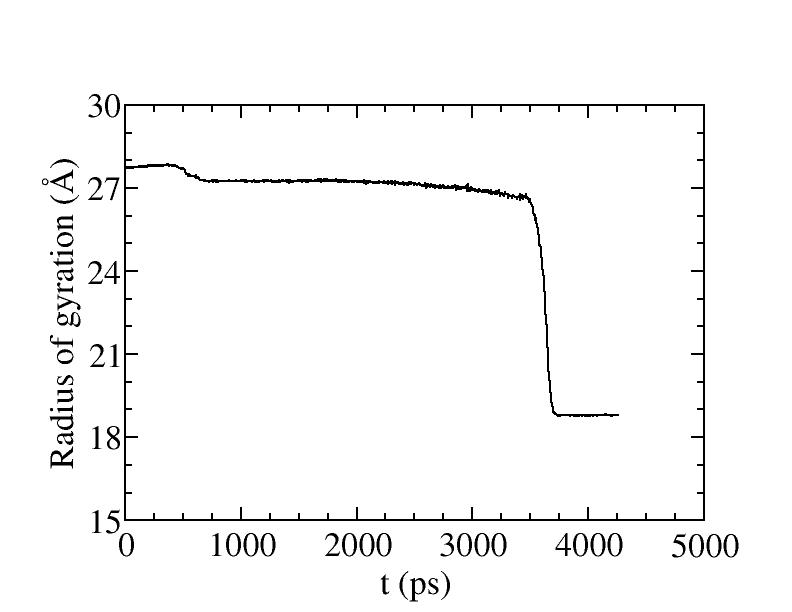

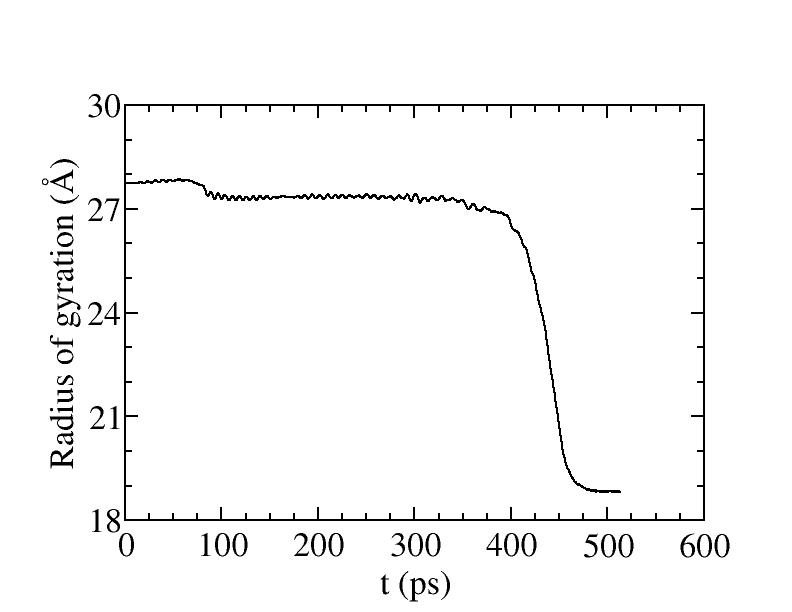

Radius of gyration vs. time

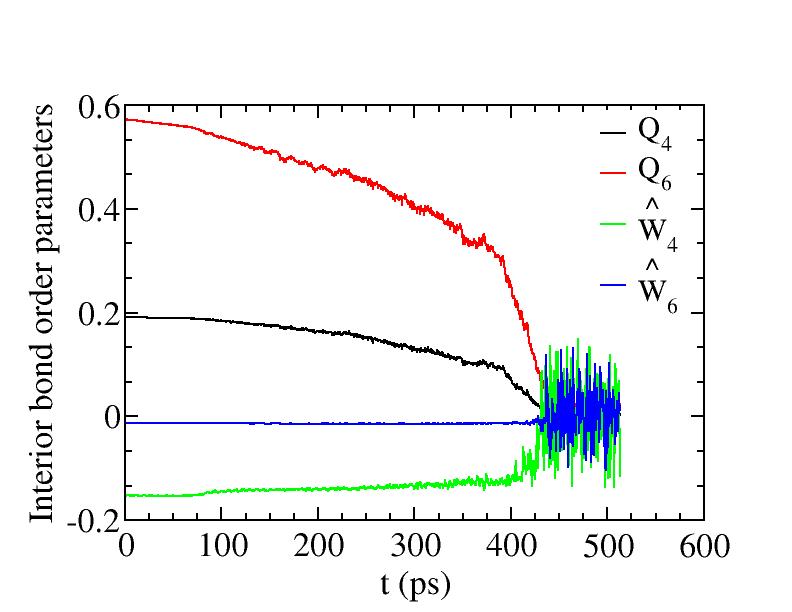

Interior bond order parameters

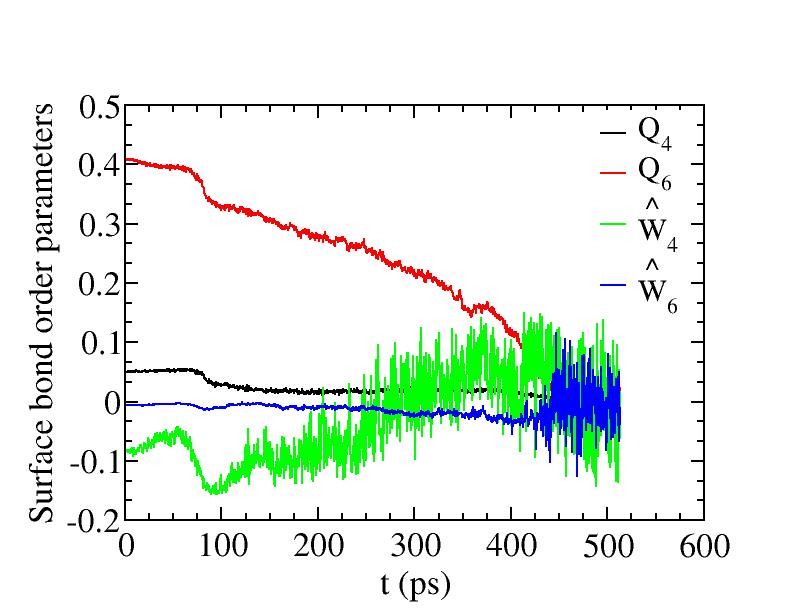

Surface bond order parameters

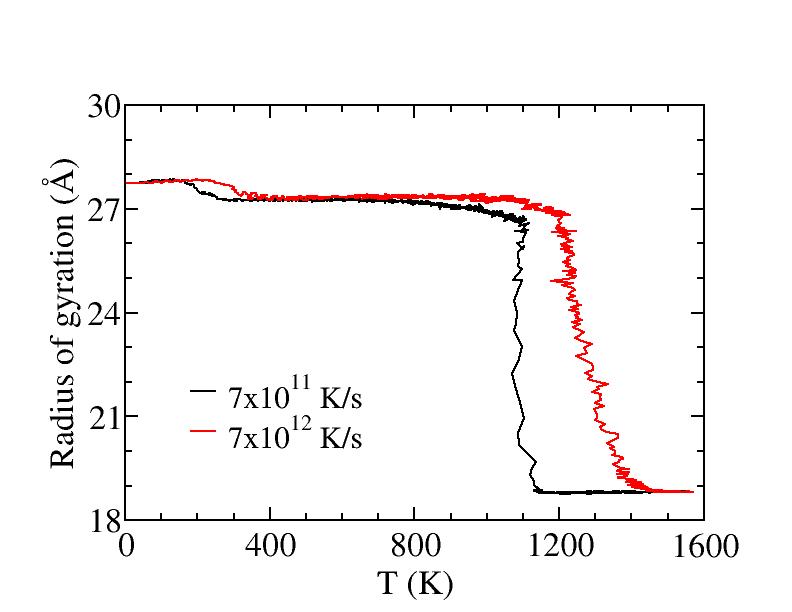

Slower heating

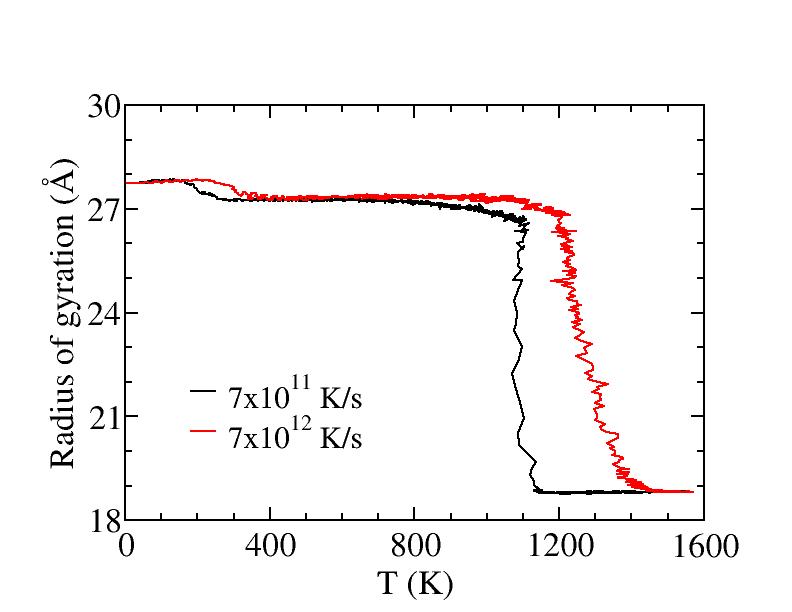

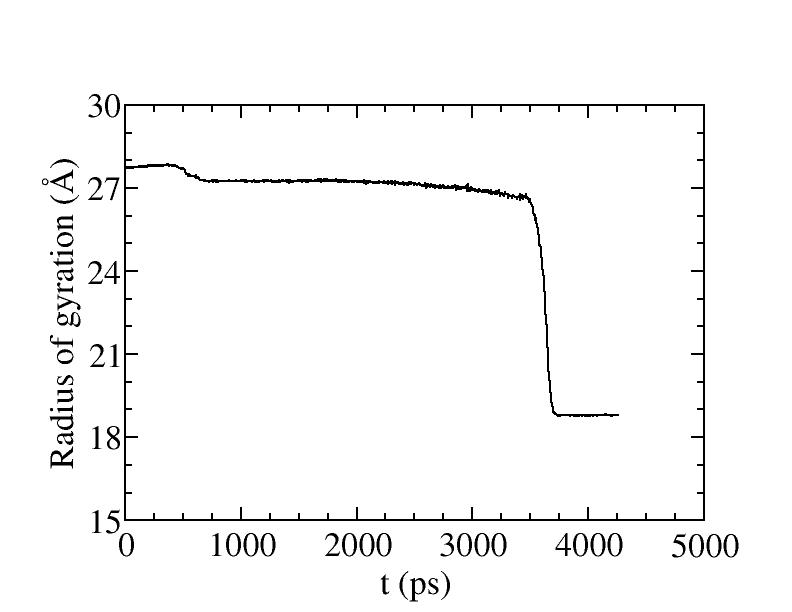

The same rod went through a similar heating procedure 10 times slower. Only

the radius of gyration is shown below.

Radius of gyration vs. Temperature